In this content, together, we face a topic of great importance both in construction and in contemporary architecture: ventilated facades. In particular, we pay attention to the technological aspect that proves to be decisive for the creation of quality and long-lasting systems and above all the main materials that can be used.

THE FUNCTIONING OF THE VENTILATED FACADE

We talked about the ventilated facade in a previous blog post that you can find here, illustrating in depth all the concepts necessary for an adequate understanding of its operation:

- Modality of heat transfer

- Overheating of indoor environments by solar radiation and conduction

- Movement of hot air masses through convective motions

Here, we only briefly report the basic practical concepts.

In fact, the ventilated facade provides for the creation of an additional external envelope with respect to the existing one of the building, namely its perimeter walls.

This casing is positioned by means of a dry fixing system, therefore of a mechanical type, positioned a few centimetres away from the rear walls. In this way, the sun’s rays do not directly affect the building, instead penetrating the ventilated facade and therefore the overheating caused by solar radiation is less.

However, in the internal cavity, which can range from a few centimetres to a few tens of centimetres depending on the design choices, the air reaches high temperatures precisely because it intercepts the heat of solar radiation.

The design of the ventilated facade provides entry and exit routes for the air masses at the bottom and top. In this way, a natural chimney effect is established and by convection the hot air rises upwards, escaping from the interspace at altitude.

For depression, outside air is sucked from below. While still hot, given we are talking about the summer period, but certainly not as much as the overheated one inside the cavity. This continuous flow of air from the bottom up ensures the dispersal of excess heat.

THE CHARACTERISTICS NECESSARY FOR THE MATERIALS THAT FORM A VENTILATED FACADE

Now, we can illustrate with greater awareness the characteristics that a material must have to be suitable for the realisation of this technology.

We split the issues in two.

1. THE SUPPORT SYSTEM OF THE VENTILATED FACADE

The support system of the ventilated facade is the set of elements, profiles, hooks and fixings that must be fitted to the wall to subsequently accommodate the final envelope.

To be clear, if you want to build the facade on an existing building in masonry or reinforced concrete, we must first affix the point anchors, guides and everything necessary to fix the cladding of the ventilated facade in a different phase, regardless of the material chosen to make it.

For this reason, it will be necessary to conduct an adequate survey lay out on the final design on where and how to position the fixing systems: if on load-bearing masonry walls, if on pillars, if on infill walls, if suitable to withstand the mechanical stresses of the case.

Let’s imagine, for example, a coating in stone slabs.

There are several ways to proceed in relation to the final design, but at the base there is always anchorage to the wall of point or linear elements, using expansion anchors or such like, which overhang, or move away from the edge of the external surface. On these, near their tops, the stone slabs will be visually appreciable from the outside.

Without doubt, the fundamental properties of these elements are:

- Good ability to resist deformation. This means in terms of construction science an elastic modulus E also called a high Young modulus.

- Resistance to bad weather, humidity, hot-cold alternating cycles, freeze-thaw.

2. THE FACADE CLADDING

In this case we are talking about the material that is fixed on the supports that we have talked about so far, in addition to functional and performance needs, it also presents aesthetic and visual needs.

It must be resistant to humidity, water and all other atmospheric agents.

But, let’s not forget, it must also better manage solar radiation, the main reason why the ventilated facade is conceived. It must therefore be resistant to ultraviolet rays over time.

It must be performing in mechanical terms just enough to handle its weight and external static and dynamic actions. For example, let’s mention the snow that could affect the split tiles slightly horizontally inclined and let’s not forget the gusts of wind that, as we rise in altitude, become more severe.

THE BEST MATERIALS FOR THE CONSTRUCTION OF VENTILATED FACADES

After outlining the main features for the construction of the support elements of the ventilated facades and external cladding, we mention the most suitable materials for the accomplishment of this task, with a look at the aesthetic and phenomenal design aspects.

MATERIALS FOR THE SUPPORT SYSTEM OF THE VENTILATED FACADE

Returning to what has been said for the support elements to be positioned on the wall (specifically designed substructure), steel is a material that does not particularly fear the factors mentioned, except humidity and water in general.

When it has to deal with these aspects, it is subjected to galvanisation or stainless steel is used.

From this point of view, aluminium turns out to be higher performing. Indeed, exposed to external agents it creates an oxide film, a few microns thick, capable of defending the internal thicknesses of the elements over time.

For structural aspects, steel is a highly performing material, with modulus E = 2100000 daN / cm2. Therefore, it lends itself very well to the purpose.

But aluminium is also very suitable. It has E = 690000 daN / cm2, which remains a respectable value, especially considering the fact that the actions transmitted by the facade cladding are not exceptionally high.

Another advantage to mention, while the weight of steel is 7850 daN / m3, aluminium weighs 2900 daN / m3. This aspect is relevant since, during the work for installation and maintenance, it is always advisable to try to limit the weight of the materials to ease difficulties for operators and to reduce the construction site risks of heavy materials.

FACADE CLADDING MATERIALS

As for the materials to be used to create the real external diaphragm of the ventilated facade, let’s look at the main materials for this type of use.

ALUMINIUM

Aluminium is the contemporary material that is most suitable for outdoor positioning. It is, as mentioned above, light and performing from a technological and structural point of view. Being the son of modern industrial production, It is characterised by a very high flexibility in production and use. We can find it in multiple formats. It is mainly applied on facade cladding systems, such as:

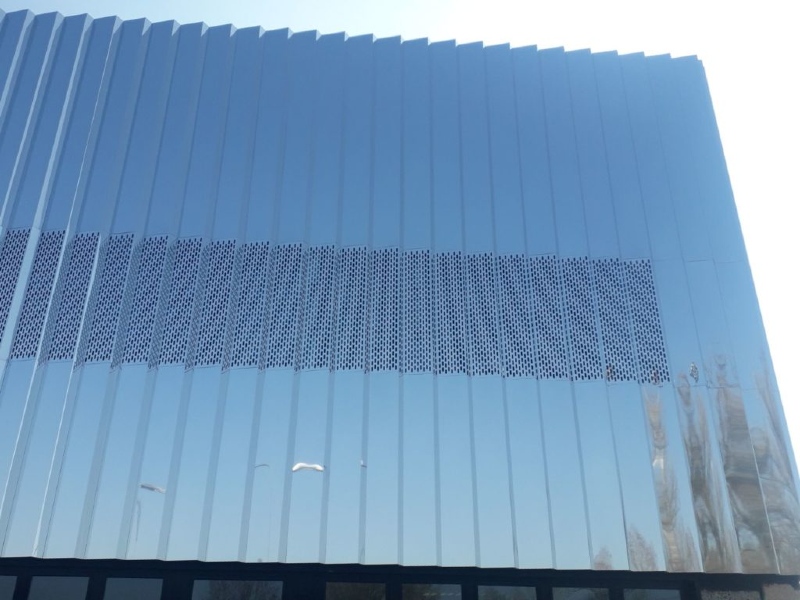

Furthermore, it can be applied, in the form of a expanded metal panel, on systems such as Tetris Mesh, or on systems with trapezoidal sheet panels, or even on a corrugated sheet panel.

The great versatility that characterises it makes it an attractive material especially for the designer. In fact, depending on the specific product chosen, its formats and the imprinted colours, aluminium can lend itself to more conservative or more innovative external solutions.

Able to marry existing and historicised contexts with a function of accompaniment and service, but also to take on the role of protagonist for avant-garde and markedly contemporary designs.

HPL PANELS

HPL panels, are high-pressure laminates, classified EDF in the EN 438-6 standard, are made with special presses through the combined action of heat and high pressure. The use of double-hardening polyurethane acrylic resins guarantees effective protection from atmospheric agents, making them particularly suitable for durable covering of balconies and facades.

This material is scratch, solvent, hail and impact resistant in accordance with EN ISO 178. Easily cleanable, it is suitable for all outdoor uses, giving the facade a perfect characterizing connotation thanks to the infinite variety of finishes.

WOOD

Wood is an ancient material of great visual and scenic impact. The beauty of its essences is beyond question. It is still used as a cladding for external facades, even ventilated.

It goes without saying that the arguments cited above ring a bell as regards the durability of the material, its maintenance and the costs associated with it. Among the pros that should be mentioned, wood is thermally insulating.

STONE

Stone is an integral part of our architectural heritage and is outlined as a material of great presence and elegance. There are multiple types of stone but, sometimes, those that most fall into our imagination, since widely used since the past, are not very suitable for outdoor use.

An example is sandstone. However, these themes need a specific focus since there are many stones of considerable durability and, even among sandstones, there are certain products that perform better than others. A 3 cm thick stone slab shields well from solar radiation, but pay attention to the weight!

BRICK

Brick, or baked clay, is an excellent solution to use. Even in many contemporary architectures it plays a lead role. Also because, thanks to today’s production technologies, the formats are among the most disparate: quadrilateral elements with right angles, quadrilateral elements with non-right angles, smooth elements, elements with superficial processing, oblong-shaped elements list type and similar.

PORCELAIN STONEWARE

Porcelain stoneware belongs to the family of ceramic materials mentioned above and nevertheless reports some improvements in terms of resistance to mechanical actions, abrasion, rubbing and impact. It is highly waterproof and can also be subjected to numerous processes and aesthetic effects. The stoneware is able to resemble the effect of wood or that of marble in a remarkably realistic way. In addition, the colours, the material effects and the formats that can be obtained leave us spoiled for choice.

POLYCARBONATE

Polycarbonate is often used in contemporary architecture due to its elegantly minimalistic nature, typical of a strong design will. The most relevant positive aspects are the great flexibility in formats, colours and in the effects of transparency and opacity. It has remarkable resistance to water.