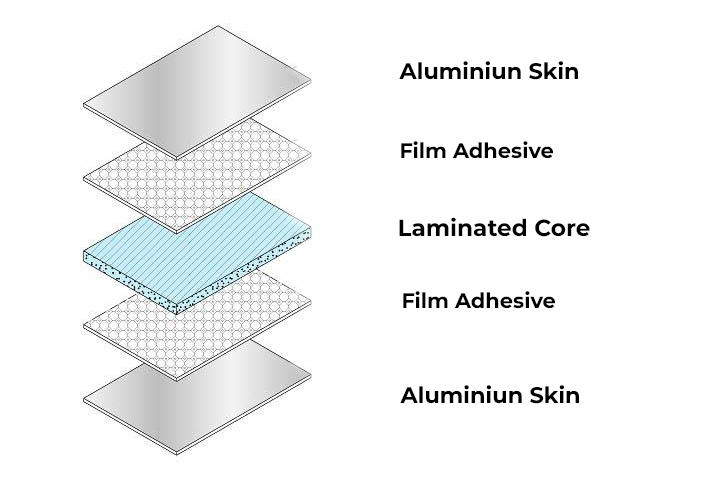

Aluminium composite is a prefabricated sandwich panel, consisting of two external aluminium faces and a central core in thermoplastic synthetic material (neoprene or polyethylene).

Light and easy to apply, it can be cut, assembled, folded and shaped in any shape and size.

This versatility has led to its use in various sectors, ranging from the design of objects, to the production of furnishing accessories and furniture, from advertising signs to the construction of exhibition stands and exhibition spaces, from the production of claddings for domestic interiors to the construction of entire architectural facades.

COMPOSITE ALUMINIUM PANELS IN THE ARCHITECTURAL FIELD

Aluminium composite is becoming the ideal choice for buildings that interpret a contemporary design concept, offering technological and functional solutions that allow easy product installation and guarantee excellent weather resistance performance, on any type of project.

Thanks to simple anchoring systems, the use of composite aluminium panels is, in fact, a widespread choice, both for building envelopes on new buildings, and for major renovations on existing buildings.

The constant demands to reduce consumption from an energy point of view, favours the use of dry construction systems and passive technologies that improve the overall energy performance of buildings, such as ventilated facades, often covered with aluminium composite panels.

Not only functionality and efficiency, but also the possibility for the designer to propose architectural projects of great visual impact, communicating all one’s own creativity through the wide range of existing or customisable finishes and colours, allowing evermore different and in any case coherent solutions with the architectural thought that the designer intends to express.

WE DEEPEN THE TECHNICAL ASPECTS: CHARACTERISTICS OF THE PRODUCTS ON THE MARKET

Depending on the different manufacturers that operate in the market, panels with different formats and sizes can be found, but in the vast majority of cases, aluminium composite products are manufactured in the standard linear dimensions of 1000 mm, 1250 mm or 1500 mm. The overall thickness of the panel can vary between 3 mm and 6 mm. With reference to the facade cladding, the most suitable thickness ranges are from 4mm to 6mm with 0.5mm skins.

The internal core makes up about 90% of the composite panel and based on the characteristics of the plastic material chosen, it can be black, grey or transparent. Two thin sheets of aluminium are applied to it by bonding which gives rigidity and stability to the final product.

An important factor, both in terms of performance and production costs, are the two aluminium cores. They can have different thicknesses ranging from 0.2 mm to 0.5 mm.

Since aluminium is the most expensive material, it is obvious that panels made of sheets with reduced thickness will have a more advantageous market price than products made of solid aluminium sheets. It is also true that the reduction in the thickness of the metal layer causes a decrease in the performance of the panel itself.

The correct choice of the thickness of the aluminium sheet is closely associated with the field of use of the final product. In case of application on simple and regular surfaces, the thickness is not a particularly decisive factor for the final outcome of the facade. While in situations with buildings with curvilinear and more complex shapes, it is recommended to use aluminium sheets with a thickness of not less than 0.3 mm. Below this value, it would be more difficult to obtain clean curved surfaces.

THE ANCHORING SYSTEM FOR ALUMINIUM COMPOSITE PANELS

The aluminium composite panels are fixed on a support substructure consisting of vertical uprights and horizontal crosspieces or only uprights, hooked, if it is a new building, to the structural skeleton of the building, (beams and pillars) or, in the case of renovation or maintenance of a property, directly to the existing facing wall.

The substructure is not designed to contribute to the static stability of the building, but designed with the task of supporting only the composite panels and, if anything, of transferring wind and rain loads to the load-bearing structure.

The substructure can be composed of aluminium profiles with “L” or “T” sections, or wooden support elements hooked by means of aluminium or galvanised steel brackets.

Aluminium composite modules can be installed in different ways:

- Face Fixed system, i.e. the panels can be fixed, in the case of an aluminium substructure, with screws or more often with rivets left exposed, almost always in tone with the colour of the panel, or hooked onto a wooden substructure, by means of stainless steel screws.

- Cassettes or boxes, a cleaner architectural solution, where no screw heads or rivets are visible, the panels are folded into a box shape and, through slots, mechanically hooked to the substructure. It is an installation system with concealed fixing.

WHY HAS THE ALUMINIUM COMPOSITE MATERIAL SPREAD WIDELY IN THE ARCHITECTURAL FIELD?

Specifically, when is it appropriate to choose technological systems with aluminium composite panels for the construction of external facades?

After this overview of the characteristics and application technologies, the reasons why the aluminium composite material has had a remarkable success and a widespread use in the field of architecture, especially in the design of external facades, are easily understood.

AFFORDABILITY OF COMPOSITE ALUMINIUM PANELS

First, there is the cost-effectiveness. Composite aluminium panels for facades have a low market price and being quite light, they do not require many fixing points. This also leads to savings on the cost of installation labour.

LIGHTNESS AND EASE OF TRANSPORT

As just mentioned, the aluminium composite is classified as a light material. To be exact, aluminium has a specific weight of about 2.70 kg / dm3, while for ordinary steel we are around 7.80 kg / dm3. This means that aluminium is approximately 65% lighter than steel and this makes it perfect for external coating systems. Light, in this case it is synonymous with easy to handle: the aluminium composite modules, in fact, are easily manoeuvrable on site and easy to install.

HIGH STRENGTH AND VERSATILITY

Lightness, but at the same time a great ability to last over time and to be able to adapt to articulated geometric architectural forms. Aluminium composite panels are extremely durable and can withstand the action of atmospheric agents for up to 30 years, keeping the original physical and mechanical characteristics unchanged. They can be cut, folded, curved, drilled, without losing their structural integrity.

HIGH CORROSION RESISTANCE

The characteristics of durability and resistance are due to the intrinsic ability of aluminium to resist corrosion. When aluminium is exposed to the air, it creates a thin layer of aluminium oxide which makes the facade resistant to corrosive phenomena. It should also be said that the materials and composites in aluminium available on the market are pre-treated with special products, forming a protective layer that makes them even more resistant to corrosion and therefore ideal for installation on buildings located in coastal contexts or in any case, in environment extremes.

LOW MAINTENANCE COSTS

Thanks to its characteristics of resistance to deterioration and wear processes, building envelopes made up of aluminium composite panels require a very low level of maintenance, compared to traditionally built facades (plaster, wood and concrete). The costs and maintenance effort of the aluminium coating systems are almost non-existent; in fact, simple cleaning processes with moderate pressure water, to be repeated once or twice a year, are sufficient to remove residual soil and dust.

TO CONCLUDE

As mentioned, the vast majority of manufacturers of coating systems with aluminium composite panels offer a wide range of shapes and colours that allow infinite design solutions.

Composite modules however, should not be considered as simple finishing elements for the facade; they are part of a casing system that must guarantee more complex performances: for example, if coupled with other materials, the composite modules offer functional characteristics such as thermal and acoustic insulation.

In addition, aluminium, being classified as non-combustible material, is suitable for all fire safety requirements. If exposed to temperatures over 600 ° Celsius, it melts, but it is not flammable, does not develop into a gaseous state nor release toxic substances.

Cost-effectiveness, lightness, durability, resistance are the fundamental characteristics that have made aluminium composite a highly efficient and functional construction material. A revolutionary material, which in contrast to traditional construction techniques in concrete and brick has marked a profound change in the culture of the architectural design, renewing the way of conceiving the building envelope.